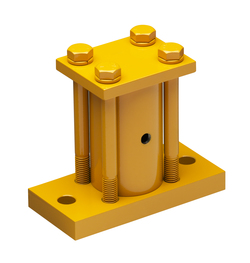

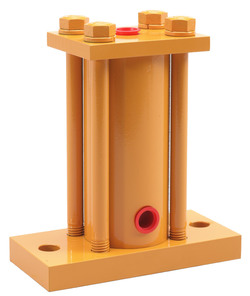

Put the sledgehammer away for good when you install a piston vibrator to keep bulk materials flowing efficiently.

The age-old practice of beating on the side of a container with a hammer to get material moving is no longer necessary with industrial vibration. In fact, Martin Engineering manufactures a line of piston vibrators that closely mimic the action of a hammer blow for truck beds, railcars, hoppers and bins. Ideal for stubborn flow problems while eliminating "hammer rash!"

However, the repeated use of a sledgehammer causes structural damage to the bin wall. Over time, the bin wall will need to be replaced. Another drawback to using a sledgehammer is the potential for employee injury. Sledgehammers are typically heavy and swinging them repeatedly can create the opportunity for back injury. Lastly, each blow to the bin wall with a sledgehammer creates a dent, which then becomes a shelf, trapping more material and making the flow problems more frequent and harder to remove.

Piston vibrators are also an economical solution that requires minimal maintenance or lubrication when powered by filtered compressed air.

Consistent Material Flow = Higher Profits!

Our technicians and engineers are available to provide expert advice and assistance on these products and all of your bulk material handling questions and problems. Please contact us today and let us help!

- Break up bottlenecks and obstructions caused by compaction

- Get material flowing freely through the discharge port

- Unload cargo and move product faster, keeping you on schedule

- Break up obstructions without having to send workers beneath the discharge

- Eliminate the need to loosen material by hammering on the sides of containers

- Protect workers from acute and repetitive-motion injuries

- Generate more throughput and boost profitability

- Reduce labor costs by eliminating the need to manually get rid of obstructions

- Save money through minimal cost of ownership, including energy costs

Try Our Product and Customer Service Risk-Free!

We are so confident we can solve your problem, we are happy to prove it to you first! Ask us about a no-obligation FREE trial and let the effectiveness of the product and the Martin Engineering technology and service convince you that we have the right solution for you!

Tell Us About The Problem You’re Trying To Solve

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Briefly Describe Your Application

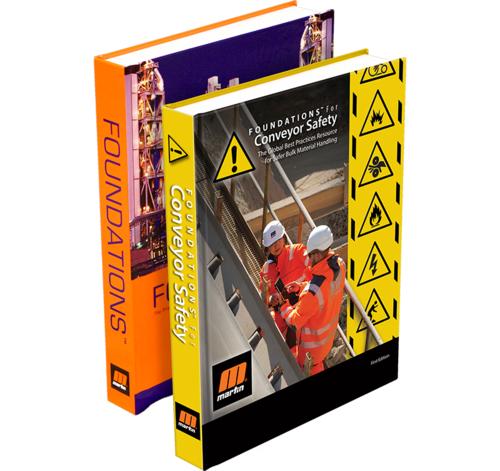

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy