THINK CLEAN®: Dirt, The Movie!

Published: July 13th 2015

Welcome back to the old geezer’s blog! (I tried to use that as our title, but the idea was vetoed.) I’d like to reach back into the treasure chest again today for a story out of the late 1960s. That was the time period when we were developing our philosophy about the effects that fugitive material has on conveyor systems -- what I call durt: carryback, spillage and dust.

Welcome back to the old geezer’s blog! (I tried to use that as our title, but the idea was vetoed.) I’d like to reach back into the treasure chest again today for a story out of the late 1960s. That was the time period when we were developing our philosophy about the effects that fugitive material has on conveyor systems -- what I call durt: carryback, spillage and dust.

It wasn’t a hot topic among conveyor operators back then, because most people adopted a “comes with the territory” attitude, as if conveyors were just inherently dirty. And many of them didn’t fully comprehend the costs of that attitude, or how durt could harm their operations. Most didn’t have any idea that a cleaner operation would be safer and more productive, and very few understood that components such as belt cleaners and sealing devices would actually pay for themselves over time by reducing maintenance, downtime and risk.

Mr. Peterson came up with the idea of doing a non-promotional film to educate engineers and end users about the issues, and to help us sell more conveyor products in the process. He engaged the services of a professional filmmaker -- the talented and respected Bob Swanson -- investing $200,000 during a period when that sum represented a large percentage of our sales for an entire year. Ed sent us around the world (literally) to capture footage at conveyor sites handling all sorts of cargo, collecting visual examples of the problems created by fugitive material. He understood the importance of educating prospective customers on how even an expensive hardware solution could result in long-term savings and improved profitability.

Equally important, we wanted to develop a message that would help convince engineers who design conveyors that carryback issues could and should be addressed, and that components to control durt should be built into their systems as original equipment. It was a huge challenge, suggesting that conveyors be engineered with greater emphasis on operating expenses and safety, and less focus on the lowest possible construction cost. And we had to do it in a way that wouldn’t be found offensive to the highly skilled and experienced people designing modern conveyor systems.

I decided that a semi-humorous parable was the best approach -- revolving around a chaotic event that resulted from poor planning. The scene was of two farmers transporting a load of chickens, using a method somewhat inadequate for the journey.

And that’s how Durt, the Movie was born. Please feel free to watch below or on YouTube.

So in 1983, together with Todd Swinderman and Mike Lindbeck, we created a 20-minute video that explained the causes and effects of spillage: dust and dirt that escape from conveyor systems – which I dubbed “durt.” Serving as an extension of Martin’s THINK CLEAN® philosophy, “DURT …the Movie” features footage from plants all around the world. This noncommercial film was a popular tool for educating bulk material handling professionals and distinguished Martin as a leader in providing solutions for cleaner, safer plant environments.

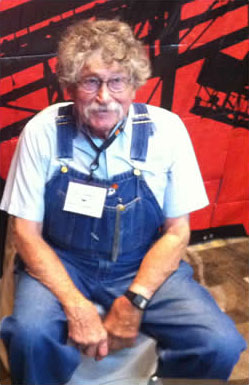

You could hardly imagine two more unlikely collaborators: Mr. Swanson was a sophisticated and accomplished filmmaker with many commercial successes (remember The Barefoot Contessa?), arriving on location in his ascot and tinted glasses. And me: a rough-around-the-edges kind of guy in my trademark bib overalls, insisting in my own uniquely diplomatic way that I knew how things had to be done in order to make our point.

I dragged that poor guy through some dirty, dusty places in far-off locations around the globe … including mines, steel mills and coal processing operations. I’m sure it was a bit of a shock for Bob after working on pristine, professionally-built sets. But he was more than up to the task, naturally adopting the authoritative tone that let all of us know he was the old pro, fully in command of actors, props and action in order to achieve our goal. At times it was very difficult to get permission from these industrial sites to allow us to shoot video of their durt, especially when we told them the film would be viewed worldwide. Some exceptional people skills were required! It took us nearly two years to complete, but the result has stood the test of time. Even today, more than four decades later, I still get comments and questions about the film.

I dragged that poor guy through some dirty, dusty places in far-off locations around the globe … including mines, steel mills and coal processing operations. I’m sure it was a bit of a shock for Bob after working on pristine, professionally-built sets. But he was more than up to the task, naturally adopting the authoritative tone that let all of us know he was the old pro, fully in command of actors, props and action in order to achieve our goal. At times it was very difficult to get permission from these industrial sites to allow us to shoot video of their durt, especially when we told them the film would be viewed worldwide. Some exceptional people skills were required! It took us nearly two years to complete, but the result has stood the test of time. Even today, more than four decades later, I still get comments and questions about the film.

That project has served us well at Martin Engineering, helping engineers and operations professionals realize that by thinking clean during the planning stages of a conveyor system, many of the components of a clean, efficient system can be designed in, providing safer human interaction with these powerful machines, while accommodating the need to inspect and maintain them properly. Considering the high cost of accidents and lost production, the movie’s message is even more relevant today than when it was made. A well-planned conveyor design will out-perform one based purely on unit cost, any day.

Remember, always THINK CLEAN!

About The Author

Dick Stahura Sr.

As a 17-year-old high schooler in Indiana, Pennsylvania, Dick had worked for a short time in a coal mine. He developed a real fondness for miners and their culture and a deep respect for the dangers of their work. Those early experiences left an indelible mark on him and motivated Dick to try to make bulk-materials handling cleaner and safer. A physics and math major at St. Francis College in Indiana, Pennsylvania, Dick was a whiz at creating and designing engineering products and had done post-graduate work in mining engineering. A self-described class clown, Dick has always used his gregarious nature and flair for amusing others as a way to connect with customers. With a reputation as a colorful character, he became known for his signature denim bib overalls, an outfit he still sports on many occasions today.