Contact us to request an exclusive pre-market trial at your plant

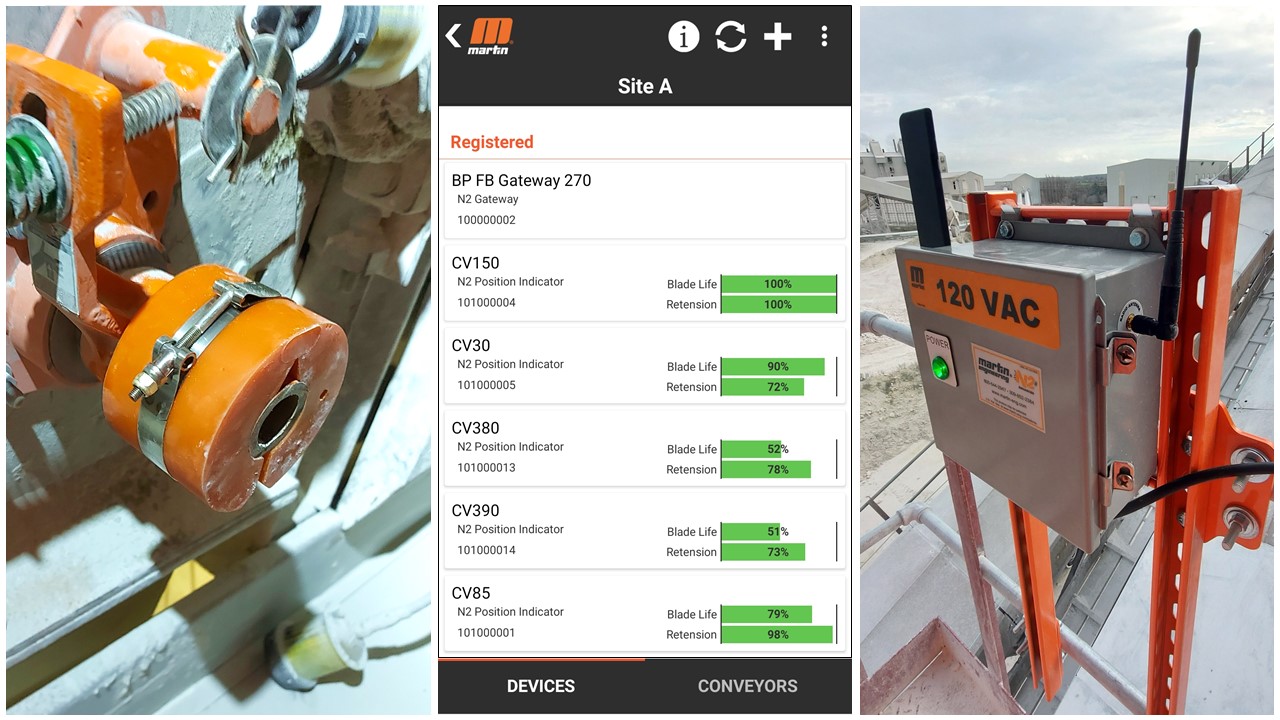

February 4, 2022A PROVEN SOLUTION! Martin Engineering's award-winning N2® remote monitoring system now has a proven track record with more than a year of performance data from a major lime works in the UK. Installing our pioneering N2® remote monitoring system on 43 conveyor belt cleaners at the flagship production site of Singleton Birch Limited has solved numerous 'pain points' such as frequent inefficient service visits, increased safety hazard touchpoints and difficulties in maintenance management. N2® is performing well, allowing maintenance planning to be simplified with detailed belt cleaner information available on demand, allowing technicians to focus on the priorities and install replacement wear parts as needed. The result is a dramatic increase in efficiency and almost 50% reduction in site visits, improving safety through reduced exposure to equipment, saving money on labour and offering a quick and calculable return on investment. Singleton Birch says: “N2® is a clever piece of kit that’s safe, saves time and is easy to use.” If you want to maximise your productivity using remote monitoring and predictive maintenance then contact us at n2_trial@martin-eng.com. |

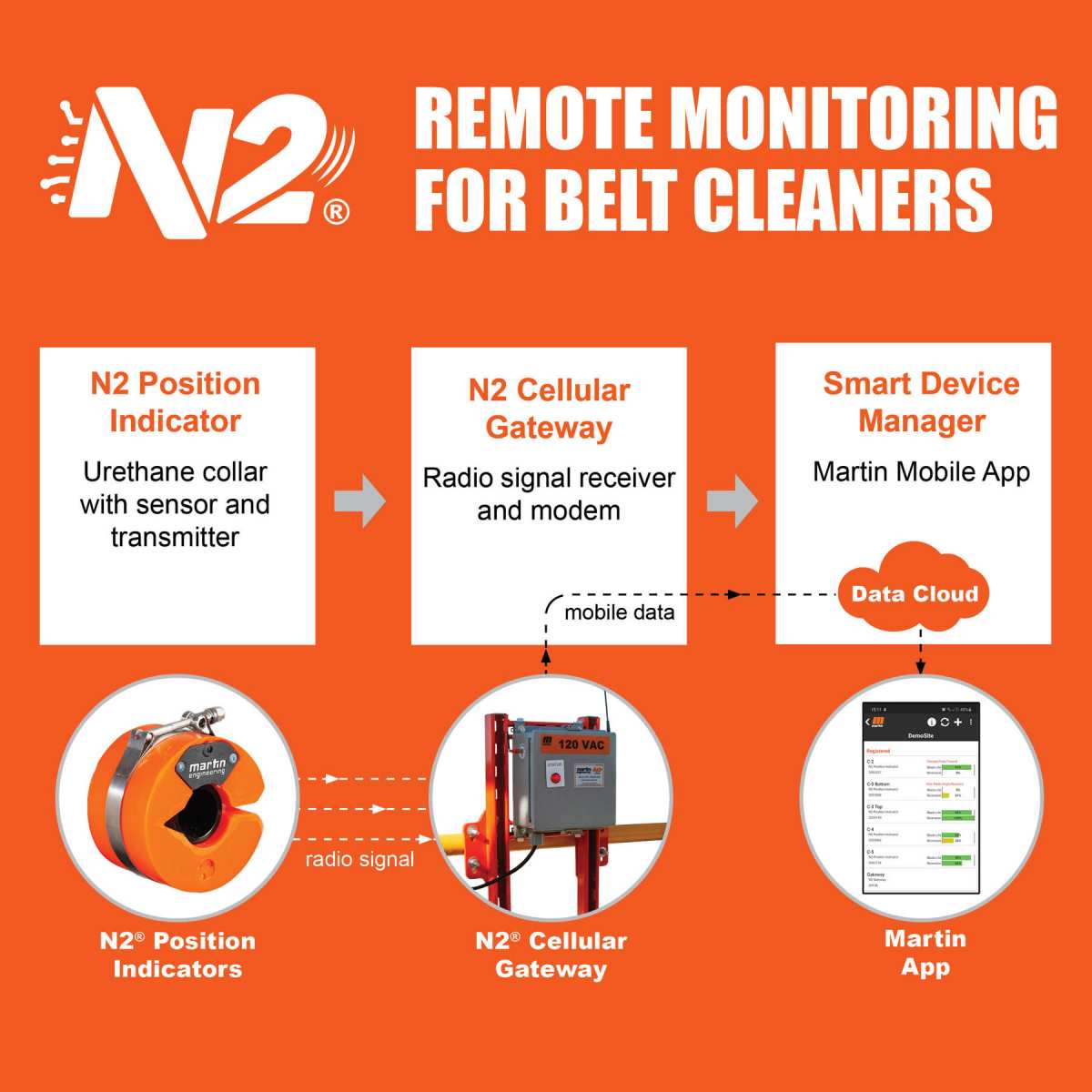

January 21, 2022N2® remote monitoring dashboard makes maintenance magement and inventory control simple to improve safety, efficiency and productivity on conveyor belts.

Contact us at n2_trial@martin-eng.com

|

January 7, 2022TURKISH DELIGHT! Trials of our revolutionary N2® remote monitoring system have just started at a Çeliktaş silica and sand quarry near İstanbul. Well done to our colleagues at Martin Engineering in Turkey, now the 9th country trialling our N2® smart technology system.

The N2® Position Indicator saves maintenance time, prevents unscheduled downtime, boosts productivity and improves safety. Thanks to N2®, maintenance teams can monitor belt cleaners via Martin’s mobile app or desktop dashboard, as well as predict when servicing is needed.

Want to find out more?

Contact us: N2_trial@martin-eng.com |

November 12, 2021GERMAN ENGINEERING! Customer trials of our innovative N2® Position Indicator for conveyor belt cleaners are now live in Germany.

The N2® PI system allows maintenance teams at bulk materials plants to monitor their belt cleaners remotely via a mobile app or desktop dashboard. N2® prevents unscheduled downtime, improves productivity, saves maintenance time, improves safety and helps with cost control.

Our team at Martin Engineering GmbH have completed an installation of the N2® system at a major cement plant near Mainz. That means Germany has become the 8th country worldwide to have revolutionary remote monitoring running on conveyors.

Want to find out more? Contact us today! N2_trial@martin-eng.com |

October 29, 2021COMING TO AFRICA! Martin Engineering‘s team in South Africa is the latest to install our revolutionary N2® remote monitoring system as part of another live customer trial!

The N2® Position Indicator for conveyor belt cleaners prevents unscheduled downtime, improves productivity, saves maintenance time, improves safety and helps with cost control. N2® allows maintenance teams at any bulk materials processing plants to monitor their belt cleaners remotely via a mobile app or desktop dashboard.

Our South African team fitted four N2® PI’s at a major industrial plant in Witbank, east of Johannesburg, which means that our N2® system is now operational in five continents – Africa, Asia, Europe, North America and South America.

Want to find out more? Contact us today!

Email: N2_trial@martin-eng.com

|

October 1, 2021WHAT’S YOU FAVOURITE DUO? The latest customer trials of our N2® remote monitoring system in Brazil bring together two super innovations that take belt cleaner optimisation to a whole new level!

When the N2® Position Indicator is used with Martin’s automatic Air Tensioner you get remote monitoring plus automatic blade adjustment. Together they’re the ideal duo, just like batman and robin, simon and garfunkel or burger and fries!

Martin’s N2® PI prevents unscheduled downtime, saves maintenance time and helps to improve productivity, safety and cost control. With N2® you can monitor all your belt cleaners via Martin’s mobile app or desktop dashboard.

Ok, so maintaining your conveyor belt cleaner blades probably isn’t high on your ‘to do’ list. Let’s keep it that way by combining Martin’s N2® PI and Air Tensioner so belt cleaning is one less thing to worry about.

Well done to our Brazilian team for becoming is the 6th country worldwide to be trialling N2® - will your country be next?

|

September 17, 2021Bonne nouvelle! Customer trials of our pioneering N2® remote monitoring system have just started at a major steel works in France. Well done to our French colleagues!

Martin’s revolutionary N2® position indicator system conveyor belt cleaner blades prevents unscheduled downtime, improves productivity, saves maintenance time, improves safety and helps with cost control. N2® gives you predictability in the palm of your hand!

That means the quarry’s maintenance team can monitor belt cleaner performance via the Martin mobile app or desktop dashboard.

France is now the 4th country in EMEAI to install N2® - will your country be next?

Contact us for details: N2_trial@martin-eng.com

|

August 20, 2021Che figata! Our pioneering N2® PI system for remote monitoring conveyor belt cleaner blades is now undergoing customer trials in Italy.

Well done to Martin Engineering Italy for getting Martin’s revolutionary position indicator system up and running at a major quarry in Tuscany. That means the quarry’s maintenance team can monitor belt cleaner performance via the Martin mobile app or desktop dashboard.

N2® prevents unscheduled downtime, improves productivity, saves maintenance time, improves safety and helps with costcontrol. N2® gives you predictability in the palm of your hand! After successful customer installations in the UK and widespread deployment in the USA, N2® is being trialled across Martin Engineering’s EMEAI region. With customer trials already live in India and Italy, which country will be next?

If you run a major quarry, mine, industrial works or materials processing facility then contact us to find out how N2® could benefit you:

N2_trial@martin-eng.com

|

August 6, 2021Predictability in the palm of your hand! In just 99 seconds our new film outlines the advantages of Martin’s revolutionary N2® PI system for improving safety, efficiency and productivity on conveyor belts.

With just a few weeks to go before N2® launches across EMEAI, now is the time to talk to Martin: N2_trial@martin-eng.com

|

July 26, 2021GO-LIVE IN INDIA: The first customer trials of our revolutionary remote monitoring system for conveyor belt blades are now underway and delivering results in India. We’re proud of our team at Martin Engineering India for installing our game-changing N2® PI system at one of India’s leading metal producers so they can monitor belt cleaner performance via a mobile app or desktop dashboard. This follows the recent Indian Infrastructure Magazine conference where Martin Engineering Vice President Robert Whetstone explained how N2® prevents unscheduled downtime, improves productivity, saves maintenance time, improves safety and helps with cost control. N2® is being trialled across EMEAI after proven installations in the UK and deployment in the USA. Soon N2® will also be up-and-trialling in France, with further pre-market trials at plants in Belgium, Germany, Italy, Mozambique, South Africa and Turkey. If you run a major quarry operation, mine, industrial works or materials processing facility get in touch to find out how you could benefit from N2®: N2_trial@martin-eng.com |

June 18, 2021Is your job about production in quarrying, mining or materialprocessing? Do you run a complex plant with multiple conveyors over a wide area? Then remote monitoring for condition-based maintenance could be right for you. How do you know? Consider three statements: (1) I see the advantages of technology (rather than perceived problems or risks). Sounds like you? Then we’re confident you would benefit from Martin Engineering’s smart N2® remote monitoring system. Coming soon to Europe, Middle East, Africa and India, N2® predicts when conveyor belt cleaner blades need servicing or replacing, and keeps you updated via a mobile app or desktop dashboard. Send us an email now to find out more: N2_trial@martin-eng.com |

|

May 21, 2021Deploying our pioneering N2® system to monitor conveyor belt cleaners remotely has meant working with some of the smartest technology service providers. We teamed-up with two trusted Amazon Web Services (AWS) IoT partners – software solutions company Green Custard Ltd. and cellular connectivity specialists Eseye. Together we’ve developed a fully automated, seamlessly integrated and instantly secure cloud-based system that delivers super-reliable connectivity to allow maintenance managers to keep on top of belt cleaner performance anytime, anywhere without the need for physical inspection. As a result, following successful UK customer trials we’re ready for rapid deployment of N2® to mining, quarrying and materials handling companies across Europe, Middle East, Africa and Indian subcontinent. To maximise your productivity using remote monitoring and predictive maintenance get in touch! |

|

March 19, 2021

Our virtual booth is now open for you to schedule a meeting with a member of our multinational team: Ask us about our innovative N2® remote monitoring system, pioneering CleanScrape® belt cleaners, comprehensive transfer point solutions or any issues of spillage, blockage and build-up you’re experiencing. And on Wednesday 31 March at 12 pm don’t miss our Vice President Robert Whetstone talking with Head of Sales & Marketing Valeria-Zimenkova about the 'challenges of creating win-win business models with internet of things solutions': |

|

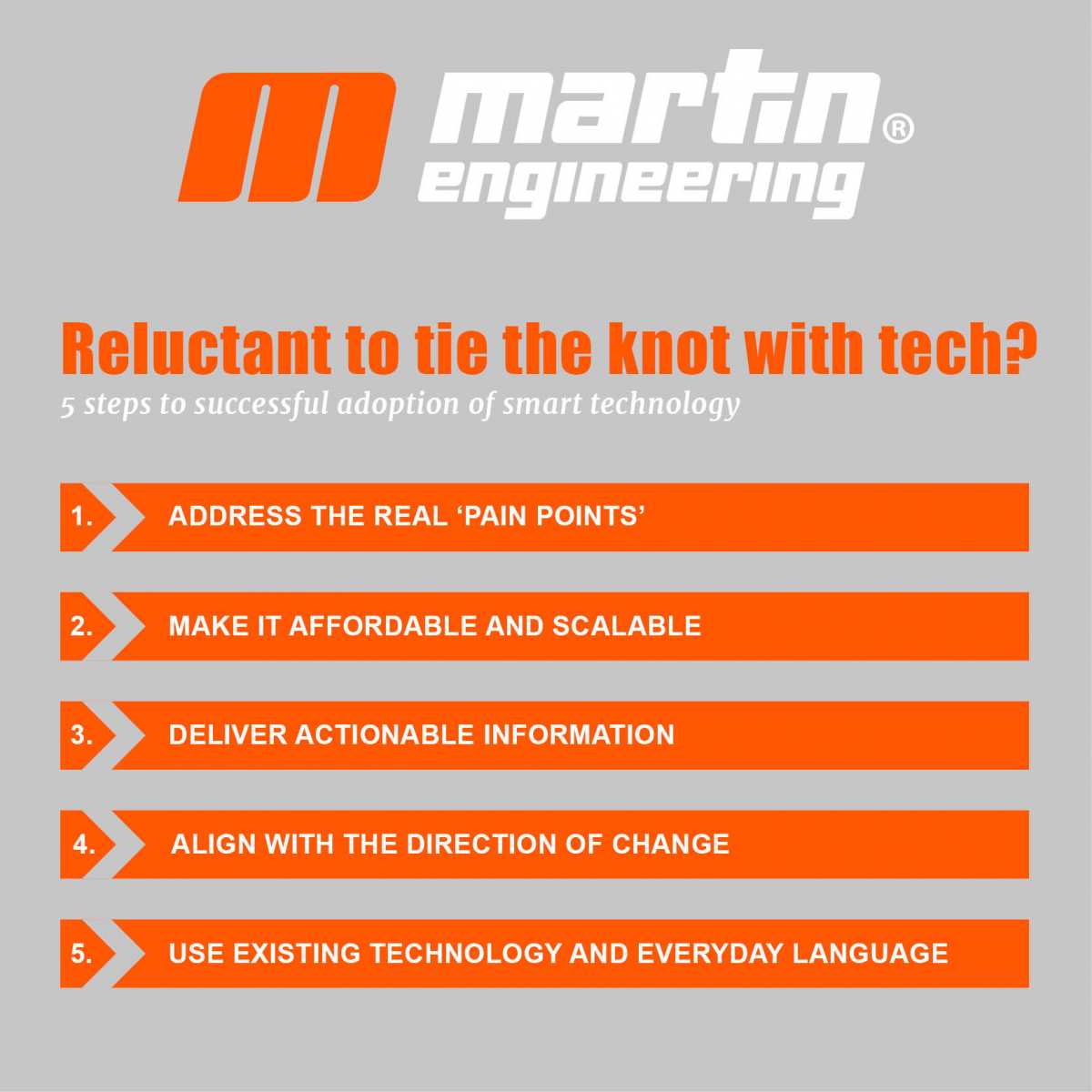

February 26, 2021Don’t ignore the Remote Revolution! Check out the new Quarry Management magazine where Martin-Engineering Vice President for EMEAI Robert Whetstone explains how to maximise productivity by using our innovative N2® remote monitoring system. “There’s a revolution happening right now in the mining and mineral processing industry that’s already giving companies competitive advantage – intelligent remote monitoring is driving new predictive, condition-based maintenance regimes.” Set to launch across Europe, Middle East, Africa and India during 2021, the N2® Position Indicator predicts when servicing is required and updates you via an easy-to-use mobile app. Read the full article and contact us to find out if you’re eligible for an exclusive pre-market trial at your plant. |

|

|

January 29, 2021The results are in! The first customer trials of @Martin-Engineering’s pioneering N2® remote monitoring system are showing impressive results after two months. So much so that our customer is expanding the installation across their entire operation! The N2® Position Indicator is a #fitnesstracker for #conveyorbelt cleaners that predicts when servicing is required and updates you via an easy-to-use mobile app (pictured centre). It cuts out needless inspection visits, saves time and effort, improves maintenance safety, helps control costs and ultimately boosts productivity. N2® PI is launching in Europe, Middle East, Africa and India during 2021 – get in touch and take advantage before your competitors do! |

January 14, 2021It takes just 99 seconds to find out about the benefits of Martin Engineering’s pioneering N2® remote monitoring system – check out our new video! The N2® Position Indicator is a smart system for #conveyorbelt cleaners that predicts when servicing is required and updates you via an easy-to-use mobile app. It cuts out needless inspection visits, saves time and effort, improves maintenance safety, helps control costs and ultimately boosts productivity. N2® PI is launching in Europe, Middle East, Africa and India throughout 2021 – get in touch and take advantage before your competitors do! |

N2 Position Indicator Update

|

December 11, 2020

And with our ground-breaking N2® Position Indicator (PI) system – launching very soon – your belt cleaners can be monitored remotely. Each N2 PI delivers belt cleaner performance data via the on-site ‘gateway’ to the cloud – from there it sends updates to your mobile device, predicting when to service or replace each cleaner blade. Using well-proven smart technology, the N2® PI reduces safety risk, saves time and effort, improves budgeting and helps with inventory control. Several N2 PI’s are already delivering performance data at one of the UK’s biggest chalk quarries and lime works, ahead of a major #productlaunch across Europe, Middle East, Africa and India from January 2021. Don’t miss the technology revolution! |

|

|

November 26, 2020Martin Engineering service teams have installed our smart-yet-simple N2® Position Indicator remotemonitoring system for belt cleaners in EMEAI for the first time. Trials are underway at one of the UK’s biggest chalk quarries and lime works – with almost 90 conveyors across the site they’re sure to benefit from our smart technology! Already proven in the USA, the N2® PI reduces safety risks, saves time and effort, improves budgeting and helps with inventory control. Automatically receiving data for every belt cleaner direct to your desktop or mobile device means you know exactly when to service or replace each blade. Next week we’ll show you more from the first installation and update you how the system is performing during its UK debut. |

November 19, 2020Martin Engineering’s pioneering remote monitoring system for conveyor belt cleaners goes into action this week in two major UK trials. Follow us on LinkedIn to watch the install and keep updated on how the trials are going. Our N2® Position Indicator removes safety risk, saves time and effort, and improves budgeting and inventory control – by sending performance data direct to your desktop or mobile device via an easy-to-use app. The N2® Position Indicator is already tried and tested in the USA and – following UK trials with our customers SingletonBirch and BluePhoenix – will be launched across Europe, Middle East, Africa and India in 2021. |

We're Here to Help

+91 20 66788270

Martin Engineering Company India Pvt. Ltd.

Plot 191, 192, 193, Vadu Khurd

Alandi-Markal Road, Phulgaon

Pune 412216, India

salesindia@martin-eng.com

+91 20 66788270