Resources

| PDF - Printable Version of Case Study | Download |

| Products Used | CleanScrape® Primary Cleaners |

|---|---|

| Product Types Used | Belt Cleaning Solutions , Primary Belt Cleaners |

| Industry | Steel |

| Customer | Arcelor Mittal NL Gent, Germany |

Arcelor Mittal Gent, which is a valued dealer customer account for CleanScrape GmbH, handles 3 MTPA of iron ore as part of its steel production process. The material is carried by two conveyors. One of the systems (a 1400 mm wide belt running at 3.5 m/s) was experiencing carryback and fugitive material, despite having primary and secondary cleaners in place from another manufacturer. The problem resulted in the loss of valuable material and required manpower to be diverted from normal tasks to do clean-up. Both of these reduced overall process efficiency and negatively impacted productivity, ultimately reducing profitability.

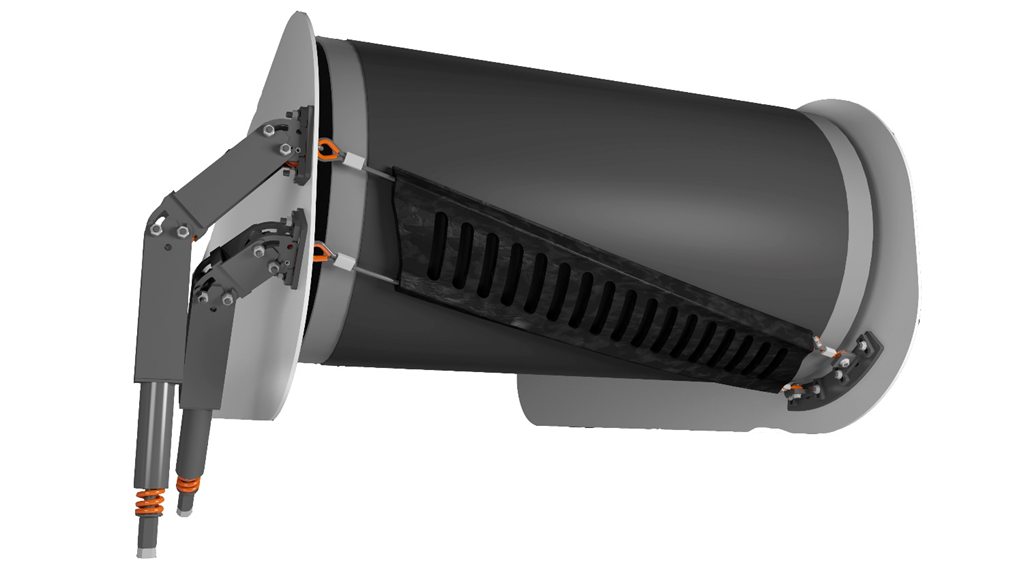

After reviewing the situation to determine the best possible solutions, making note of the high speed of the conveyor and the abrasive nature of the cargo, the CleanScrape GmbH team and the dealer's engineer recommended installing a Martin® CleanScrape HD primary cleaner to replace the existing 2-blade system. Unlike conventional belt cleaners that are mounted at a 90 degree angle to the belt, the CleanScrape cleaner is installed diagonally across the discharge pulley, forming a 3-dimensional curve beneath the discharge area that conforms to the pulley’s shape. The unique design incorporates a matrix of tungsten carbide scrapers and is tensioned lightly against the belt to prevent damage to the belt or splices.

Despite extremely low contact pressure between belt and cleaner, the CleanScrape design has been shown to remove as much as 95% of potential carryback material. The innovative cleaner is ideally suited for both slow and fast conveyor belts, including those with mechanical splices. After 16 months in operation, operators report outstanding cleaning efficiency, with no adjustments or other maintenance required. They estimate that 80% of the wear life remains. "We are happy with the cleaner's performance and installation," observed Arcelor Mittal Support Manager Tim Vertriest.

| PDF - Printable Version of Case Study | Download |