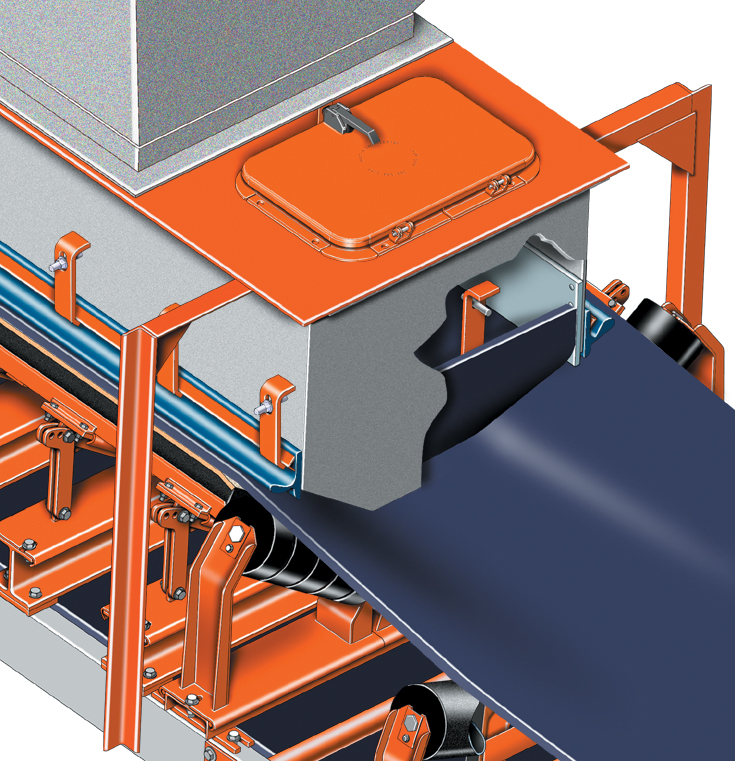

Tail Sealing Box

To conquer the age-old problem of material spilling off the tail of the conveyor, install the Martin® Tail Sealing Box. Installed on the rear of the chutework, the box uses Martin® ApronSeal™ Skirting and Strip Rubber to create an effective seal to keep material on the conveyor.

Features and Benefits:

- Seal keeps material from sliding off the belt

- Belt motion deflects tail seal to prevent accumulation at back of box

- Deflected sealing strip contains rollback without scraping off adhered material

- Return material to belt through easy-opening Martin® Inspection Door

- Field-welded on chute wall to ensure precise fit

Our technicians and engineers are available to provide expert advice and assistance on this product and all of your bulk material handling questions and problems. Please contact us today and let us help!

Paper Plant Having Trouble With Fugitive Material

Transfer Point Solutions Increase Productivity At Container Board Plant

Power Plant Needs Cleaner, Safer, More Productive Material Handling System

Transfer Point Products Improve Severe Spillage And Dust Problems

Spillage Problems Corrected By Transfer Point Redesign

MartinPLUS® Installation Services Redesign Power Plant Transfer Points

Transfer Point Solutions Resolve Carryback At Kentucky Energy Plant

Martin Transfer Point Products Reduce Risk Of Fire Or Explosion

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Briefly Describe Your Application