| Products Used | Eco Settling Zone , ApronSeal™ Single Skirting HD , Dust Bag , Dust Curtain , External Wear Liner , Self Adjusting Skirting HD |

|---|---|

| Product Types Used | Dust Management and Containment Solutions , Belt Sealing , Dust Containment |

| Industry | Pulp and Paper |

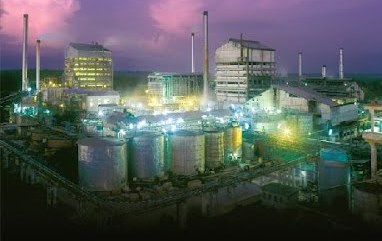

| Customer | West Coast Paper Mills Ltd. |

Problem

West Coast Paper Mills was experiencing excessive dust and spillage issues from two 650 mm wide conveyors transporting lime, as well as potential health/safety issues from airborne particulates. The conveyed material is a very fine powder, with virtually no moisture content, and the problems were particularly severe in the loading and settling zones. Dust would cling to all of the horizontal surfaces, and significant amounts of spillage accumulated on floors, walkways and under the conveyors. Operations personnel wanted to reduce the potential hazards and material waste by improving the conveyor sealing and dust collection.

Solution

Martin service technicians visited the site and recommended a combination of passive dust management and fugitive material controls to alleviate the problems. With the Martin Service Technician supervising, customer personnel assembled a Martin® Modular Chute Box, with Martin® External Wear Liner along the length of the loading and settling zones. They outfitted the rebuilt chute with Martin® BOCO Skirting to better contain the load and Martin® Apron Seal to help prevent fines from escaping. Dust curtains were added to control the air flow and improve settling, with a Martin® Dust Bag to use the positive air pressure from the chute as the driving force for filtration and reduce the local overpressure around the loading point.

Result

The improved containment was immediately apparent upon start-up, with a dramatic reduction in spilled material and airborne dust. All components have successfully withstood operating temperatures as high as 150°C. According to a customer spokesperson, "After 6 months of operation, we have found that the solutions provided have been performing satisfactorily and have significantly reduced the dust, spillage and the manpower involved in cleaning up the fugitive material. We are happy with the performance, service and overall functioning of the Martin Engineering India team." The customer plans to implement the same solution with belt cleaners for another of its conveyors.

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Briefly Describe Your Application